Come and celebrate ARC SEAM HDR Ricky (Zefeng) Wu's completion of his PhD candidacy.

Abstract

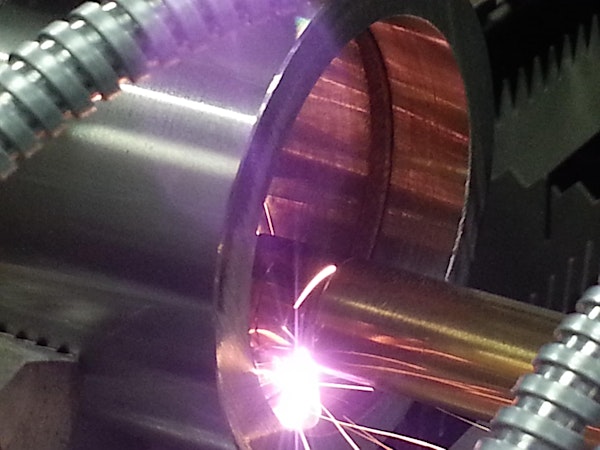

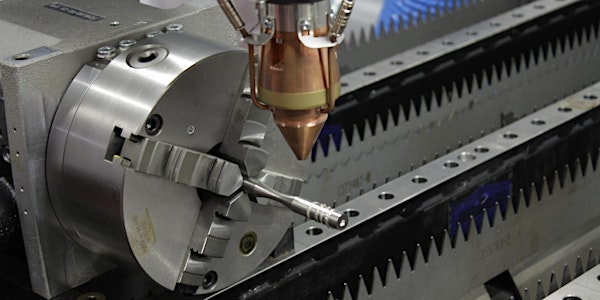

High-speed laser directed energy deposition (HS-L-DED) process is gaining traction in coating applications and repair, driven by its high production efficiency and minimal disruption to substrate materials. 300M steel is a low-alloy ultra-high-strength steel, commonly used for manufacturing of aircraft landing gears. The component surface requires wear resisting coating which has been traditionally applied by electrolytic hard-chrome (EHC) plating. However, the increasing environmental concerns of electroplating processes are stimulating a search for alternative coating and application processes, such as the HS-L-DED process, to reduce its environmental impact. Stellite® 6, a commercially developed hard-facing cobalt alloy, exhibits a potential compatibility to HS-L-DED process, but a further study is required to explore the key contributors to its deposit formation and microstructural evolution when deposition speed exceeds 10 m/min. This thesis contributes to the evolving field of HS-L-DED, offering insights into deposit formation, process optimization, and the potential for superior Stellite® 6 coatings with enhanced wear resistance and bond strength to steel substrates. The research findings deepen the understanding of microstructural evolution of Stellite® 6 alloy during rapid solidification. Further research is recommended to enhance the understanding of high-speed melt pool formation and its implications on deposit quality.

About the speaker

In 2013 Ricky graduated with a Bachelor of Engineering (Metallurgical Engineering)from the Western Australian School of Mines at Curtin University . Following this he spent time as the Secretary then Technical Event Coordinator for the Australasian Institute of Mining and Metallurgy while working as a Lab Technician for Kalgoorlie Consolidated Gold Mines.

A move to Victoria to work with Wilmar Sugar Australia Pty Ltd preceded Ricky's completion of a Master of Engineering at RMIT where he went on to be one of ARC SEAM's first recruits on a HDR Scholarship. Undertaking placement with Rosebank Engineering/Ruag throughout the pandemic years, Ricky has shown tremendous resilience and determination along with excellence in research to now be graduating from RMIT's PhD program.